Problem Statement

An industrial heating system SME manufacturer required a state-of-the-art Industry 4.0 IoT controller to meet the demand for a diverse range of precision industrial process control applications and to help their wider markets in HVAC (Heating, Ventilation & Air conditioning) provide more energy-efficient and manageable operation.

The product has to be easy to use by operators and easy to configure by installers in different deployment contexts. An interactive graphical user interface was proposed as the best way to cover the scope of features for each application area, but further application-specific UIs and branding were required.

The product targeted high-end users with high standards in brand quality, regulatory compliance and performance.

The Challenge

Developing secure and robust firmware for a single IoT sensor, let alone a complex real-time control system products, introduces many performance and design challenges, which are particularly challenging in combination:

- Real-time processing,

- TCPIP networking,

- Field bus networking

- IO & Signal calibration

- Graphics & UI Widgets

- Complex IoT business logic

The base-product’s UI and control system design required multiple well designed configuration pages suitable for installers and operators. To allow for a diverse range of bespoke applications multiple software builds were envisaged to ensure usability in each application was appropriate.

Firmware conformance to the EN60730 safety standard required for domestic and light commercial control products was also a highly desirable feature to address some light industrial applications.

The list of mandatory and highly desirable functional requirements and roadmap considerations included a number of potentially challenging implementation approaches:

- 100% configurable and operational in fully disconnected cases.

- Hardware Portability: Ensuring the software would work on different hardware to mitigate supply issues the organisation had previously faced and also allow for unit cost-optimised variants in the future.

- Validation and Optimisation: Functional and performance testing across prototype and production hardware to maintain real-time control integrity and robust connectivity.

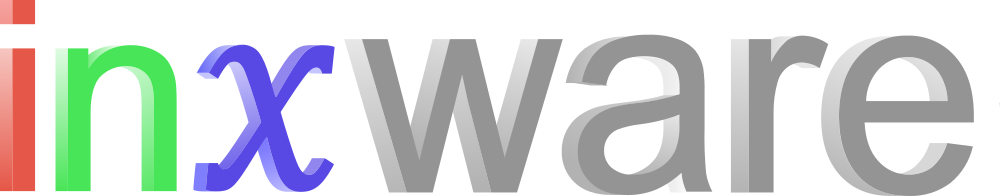

- In-built data visualisation and energy management displays.

- Auto-configuration (IoT on-boarding, controllers, networking and power management).

- WiFi support for future use-case variants

The complexity of just the basic features using conventional firmware development methods would have been unaffordable for an SME.

The Solution

The inxware platform was already available for the micro-controller platform that was selected as the basis of the proposed product design. The sub-$5 micro-controller is market-leading in features for the product specification, but conventional firmware SDKs available required substantial expertise to produce even a prototype and were also prone to stability problems if not used correctly and precisely.

The inxware platform already supported most of the building blocks required to implement the design:

- Multi-channel PID Control with interlinked safety features

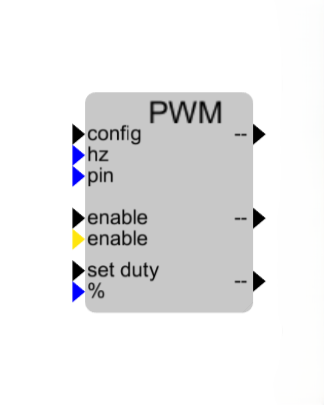

- GPIO and hardware PWM

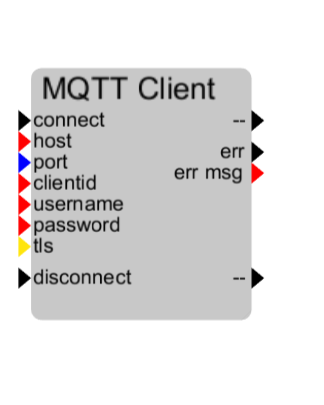

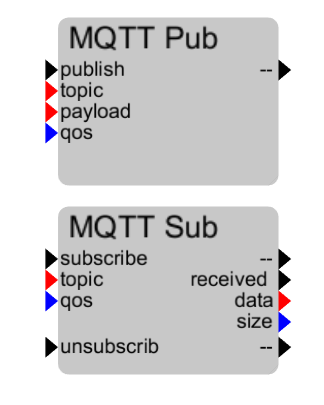

- MQTT & TLS security

- Analogue data measurement and signal conditioning

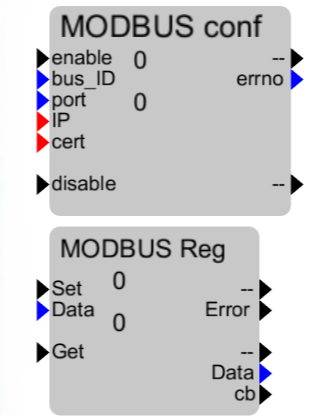

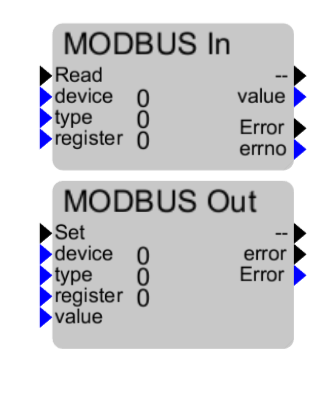

- MODBUS-Master and Slave mode RTU/TCPIP

- Real-time clocks with network clock synchronisation and wall-clock scheduling support

- Embedded GUI (HMI) widgets and gesture capable touch screen.

- Ethernet and Wireless Networking with configuration for WiFi and TCPIP.

- EN60730 hardware, data and control flow integrity checks

- State machine support for robust error and mode support.

Results and Benefits

Inxware was not only able to quickly deliver a single complex application to the customer it also allowed for the other multiple applications and bespoke applications to be developed using the no-code Lucid IDE instead of a conventional SDK.

By adopting a no-code approach, the project saw significant advantages:

- A part-time product manager and single software engineer were able to build and test the application (300 function blocks and over 100 HMI features) in 3 months

- Much of the application and UI was designed and tested on Microsoft Windows Desktop PCs with no need for hardware (standard hardware was emulated for different platforms).

- The hardware design team were able to use Lucid to debug and validate the hardware and board bring-up process.

- Time-to-market was drastically reduced, and early sales opportunities (based on revision 1 hardware samples) were achieved by the client.

- Functional testing and application validation were achieved largely in parallel with development, where test applications could be routinely sent to the device to check any firmware porting (e.g. GPIO, ADCs mappings remained intact and calibrated).

- A factory configuration, calibration and IoT provisioning application could be installed on first boot that is able to call to the application server to download user applications as required.

- Long-term maintainability was secured, thanks to OTA support and a flexible, modular development structure

This case study demonstrates how inxware’s hardware independence and encapsulation of difficult embedded software components can revolutionise product design, development and deployment. inxware avoided the many distracting complexities of traditional firmware development and deployment, and the small project team was able to communicate issues and ideas quickly in the graphical no-code software environment, not only avoiding the network effects of larger teams but accelerating individual progress measurable in hours rather than days.