Problem Statement

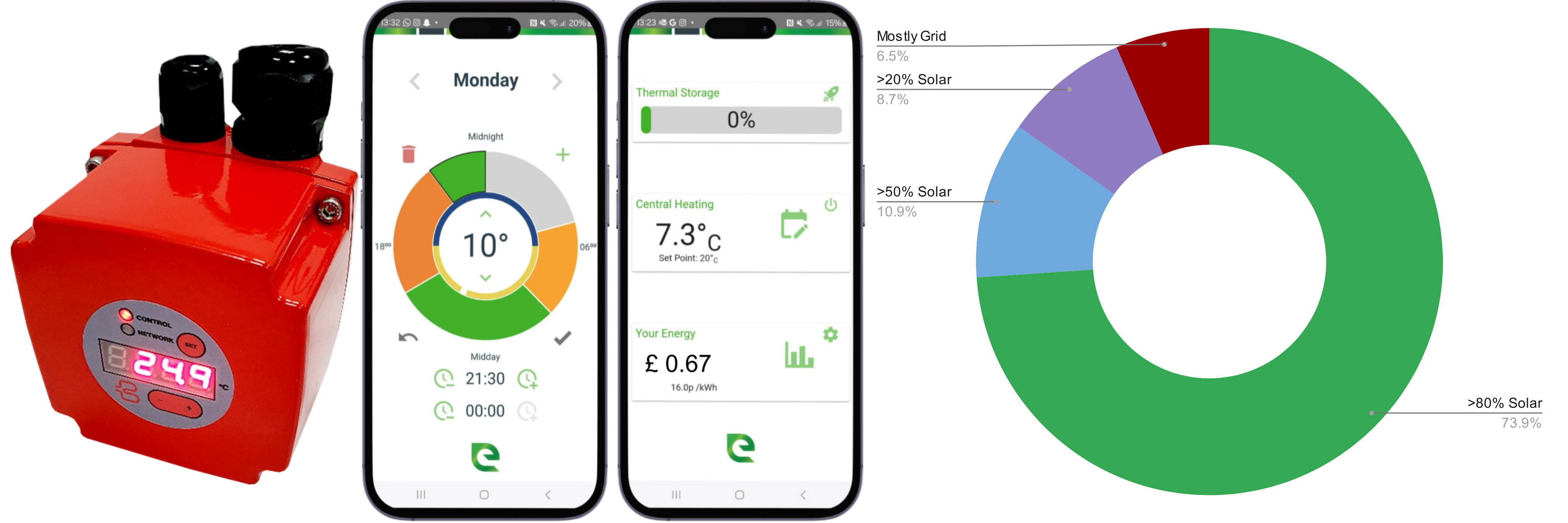

Our customers found that the way energy is produced and consumed has an enormous impact on cost effectiveness and return on equipment investments. Data-driven consumption can not only reduce energy waste but also ensure it is consumed when abundant and not over-stretching supply when it is scarce or expensive. IoT-enabled devices include smart meters, smart hot water heating, smart climate control (HVAC), adaptive lighting, smart sockets, micro-generation, battery & thermal storage, Time-of-Use (ToU) tariffs, and Demand-Side Response (DSR) benefits, which that some energy providers support. These technologies aim to reduce energy waste, lower utility bills, and decrease environmental impact.

However, the ecosystem for smart devices is constantly changing depending on national policy changes, global energy crisis and the rate of innovation by energy providers, service providers and OEM product developers. Users at levels of technical awareness are frequently unable to keep abreast of the technology and and OEMs and service providers frequently overcome with support their users.

The Challenge

Excellent product design and management was critical to making commercially viable IoT-enabled consumer products. Even the most experienced product designers and managers depend on iteration when identifying side effects of real-life use cases and usability factors, especially for smart products. The opportunities presented by IoT and embedded AI can lead designers to features that may be good or bad for end users. Features can become complexity multipliers rather than minimisers and it is often only in real-user environments that some of these issues manifest.

Fast iteration with minimal technical hindrance and introduction of side effects is a key capability for product managers when making great products in competitive time-scales.

In addition to the above business logic iteration the ability to utilise key technologies is also a key differentiator of good and bad products that are built with the most appropriate hardware and form-factor. PoC designs are often based on what was easiest to prototype in software, but the go-to-market product must be physically and economically fit for purpose, too, or it will be quickly rejected on product quality or unit price. A rapid roadmap from PoC designs to production provides OEMs and service providers a difficult process of mitigating risk and avoiding duplication of engineering.

Access to pre-established technologies that are available for PoC and production hardware is a highly desirable development process advantage that allows the product manager the ability to choose when a product is ready to go to market without waiting for the surprises of production-ready implementations.

Key Technology Components

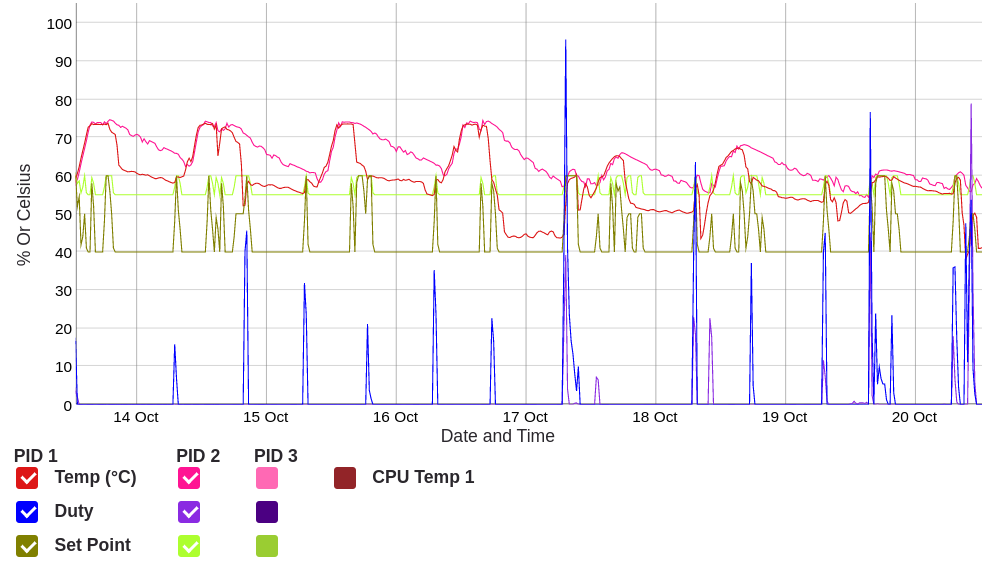

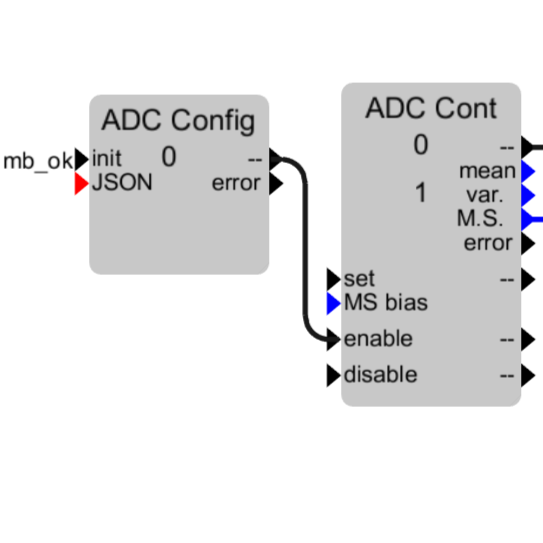

- Reliable and safe closed control (PID)

- Schedule generation, storage and communication.

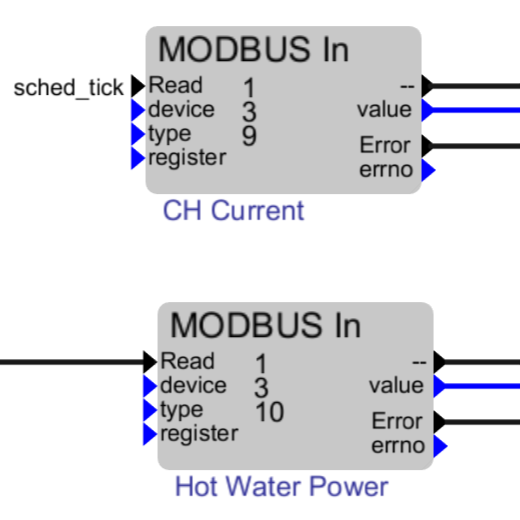

- MODBUS/RS485 system communication.

- Secure networking and key exchange.

- Secure boot and root of trust key management.

- Local Wireless connectivity (e.g. WiFi, Zigbee, Thread/Matter, LoRaWAN).

- Consumer User interfaces and configuration panels.

The Solution

Inxware provides out-of the box access on multiple hardware platform to the key building block technologies that consumer and commercial heating systems often require

- OTA no-code applications to support change management of service providers

- Reliable and safe closed control (PID)

- Schedule generation, storage and communication.

- MODBUS/RS485 system communication.

- Secure networking and key exchange.

- Secure boot and root of trust key management.

- Local Wireless connectivity (e.g. WiFi, Zigbee, Thread/Matter, LoRaWAN).

- Consumer User interfaces and configuration panels.

- Secure cloud service connectivity (e.g. MQTT).

- OTA firmware updates for key technology and security updates.